12-29

2025

2026 TMTS Taichung International Convention and Exhibition Center (TICEC)

Kaicheng will participate in the annual event held at the Taichung International Exhibition Center (TICEC) from March 25 (Wednesday) to March 28 (Saturday), 2026. During the exhibition, we will showcase our latest product technologies and innovative applications, and engage with industry partners to discuss market trends and future development directions. We sincerely invite you to visit us on site to experience Kaicheng’s professional services and innovative achievements firsthand.

MORE

10-27

2025

TMTSME 2025 Taichung Machine Tool & Smart Manufacturing Exhibition

KAI CHENG sincerely invites you to visit the upcoming TMTSME Exhibition and explore with us the latest CNC machining and automation solutions. During the exhibition, we will showcase a variety of innovative technologies and equipment designed to help you enhance production efficiency, optimize manufacturing processes, and create new business opportunities.

MORE

02-09

2025

TIMTOS Int'I Machine Tool Show March3-8,2025

We sincerely welcome you to TIMTOS 2025 – the Taipei International Machine Tool Show. At this exhibition, we will showcase our latest technologies and innovative products. We look forward to exchanging ideas with professionals from all sectors and exploring the future of smart manufacturing together.

MORE

11-12

2024

Tai chung 2024 machine Tool Exhibition

Kai Cheng will participate in the Taichung 2024 Machine Tool Exhibition from November 21 to November 24. We sincerely invite you to visit our booth and provide your valuable guidance!

MORE

12-05

2023

TMTS 2024 Taiwan International Machine Tool Show

The theme of this year's exhibition is "Dual-axis Smart Manufacturing X Sustainable Future DX & GX for a Sustainable Future", focusing on digital transformation and green transformation as the two main exhibition axes. Kai Cheng cordially invites you to join us!

MORE

10-20

2023

Tai chung 2023 machine Tool Exhibition

Exhibition: We invite you to visit our booth at Tai chung 2023 machine Tool Exhibition show during November 3 ~ 7.

MORE

11-20

2023

Kaicheng latest news and event information

"Kai Cheng: Helping clients enhance competitiveness"。

MORE

06-08

2023

KAI CHENG New Website Online

Kaicheng's new official website is online.

MORE

05-16

2023

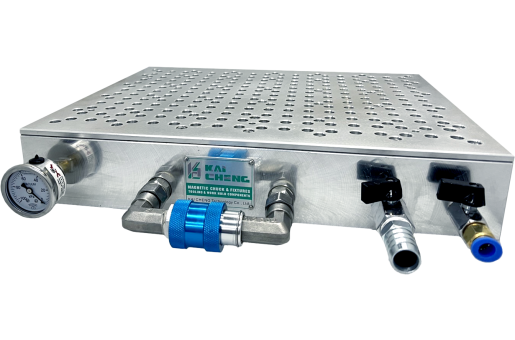

VACUUM CHUCK-KAI CHENGCO.,LTD:Solving Your Machining Problems

kai Cheng Vacuum Chuck : Solving Your Machining Problems

MORE

03-11

2024

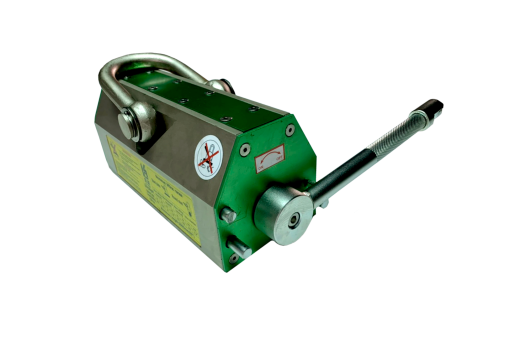

what's Switchable permanent magnetic lifters?

Switchable permanent magnetic lifters are devices used for handling and lifting metal objects

MORE

03-12

2024

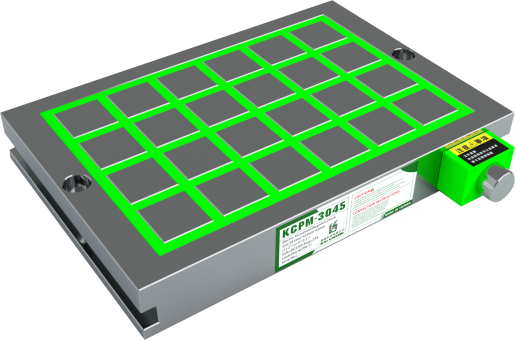

"Kai Cheng" Electro-Permanent Magnetic Chucks: Breaking Technological Barriers, Leading the Wave of Industrial Innovation"

This article will delve into the technical features of the Kai Cheng Electric permanent Magnetic chucks, as well as its applications and prospective developments in various fields.

MORE

12-27

2022

A win-win situation for precision and efficiency: the outstanding performance of permanent electric chucks in motor production

After using the permanent magnet electromagnetic chuck in motor reducer manufacturing, production efficiency increased by 45%, processing quality remained stable, and the product qualification rate reached over 98%. Following installation and training, workpiece fixation time was reduced by 60%, production costs decreased, and delivery cycles shortened, significantly enhancing market competitiveness and demonstrating the superior performance and value of the permanent magnet electromagnetic chuck.

MORE

Page :