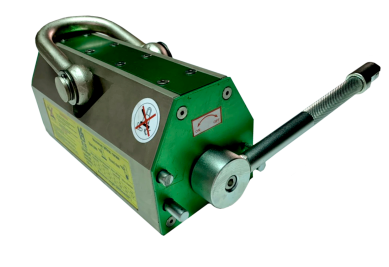

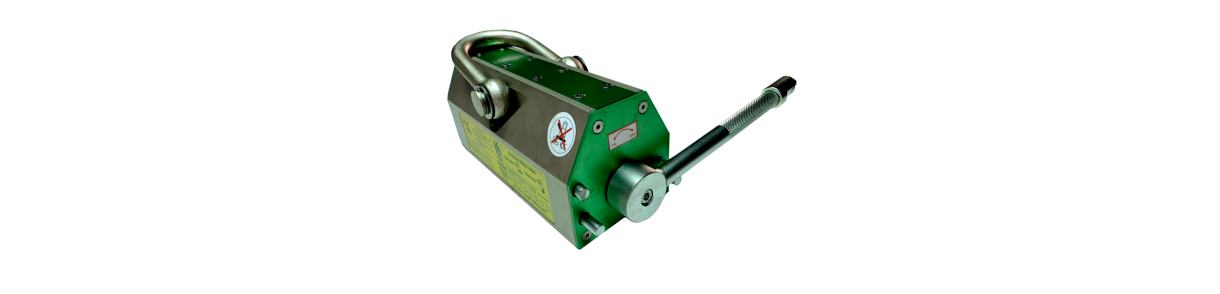

Permanent Lifting Magnet

1. Advanced Technology

Manufactured with the latest neodymium-iron-boron (NdFeB) magnetic technology. Compact size, lightweight design, and cost-effective with powerful magnetic force.

2. Permanent Magnetic Design

Operates without electricity and never demagnetizes — eliminating power failure risks and wiring hassles. Safe and energy-saving.

3. Unique V-Groove Structure

Patented V-groove design securely lifts both steel plates and cylindrical materials with a safety factor of 3.5×, ensuring stronger magnetic force and higher operational safety.

4. High Safety Factor

Each model’s rated lifting capacity equals one-third of its tested magnetic force.

For example, model KCMC-M600 has a rated lifting capacity of 600 kg, while its actual tested magnetic force reaches 2100 kgf — providing enhanced safety assurance.

5. Wide Application Range

Ideal for handling steel plates, iron blocks, cylindrical materials, machine parts, stamping molds, plastic molds, and other ferrous materials.Lifting capacity may vary depending on steel thickness, surface roughness, material type, and cleanliness.

Page :